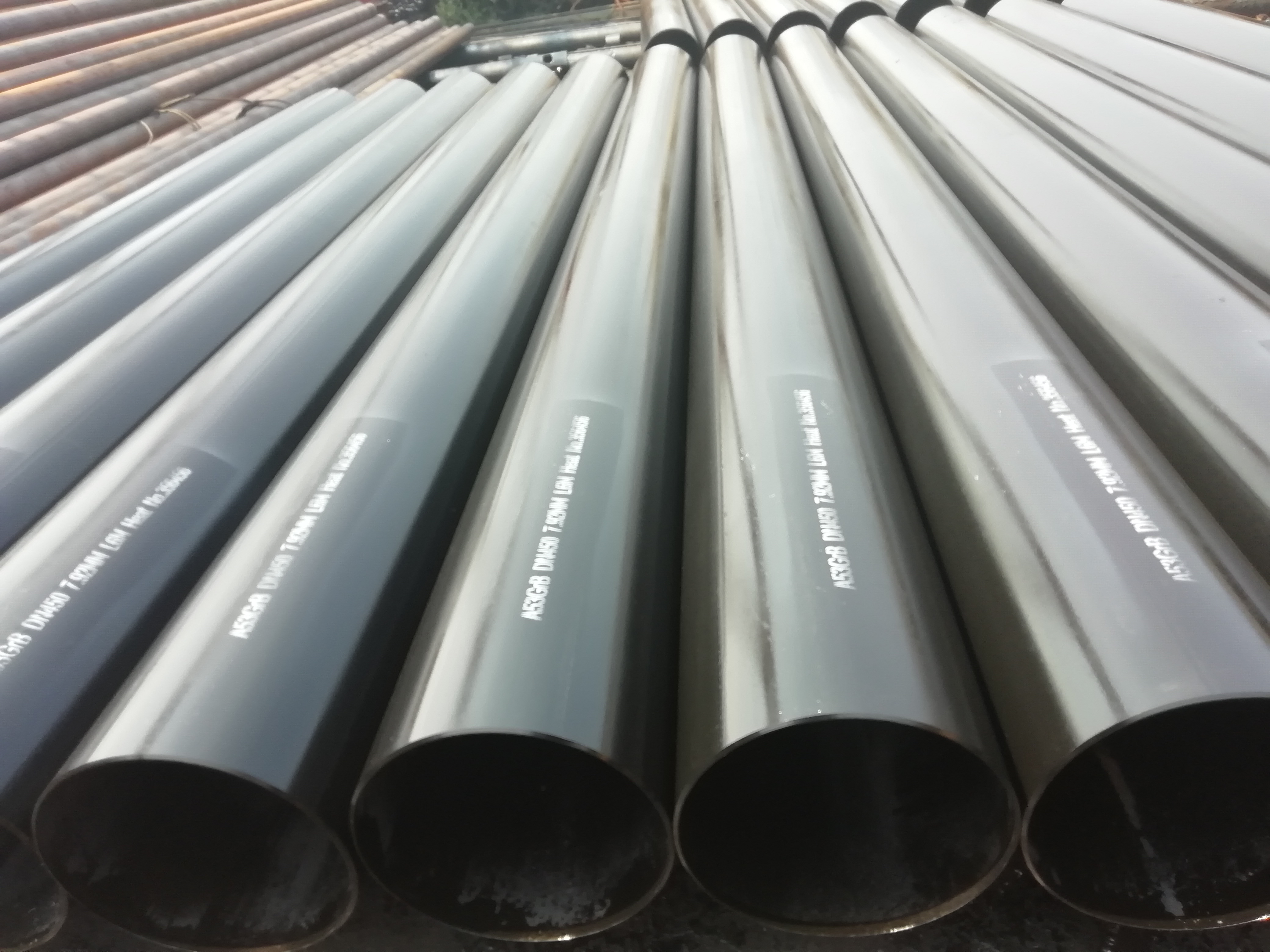

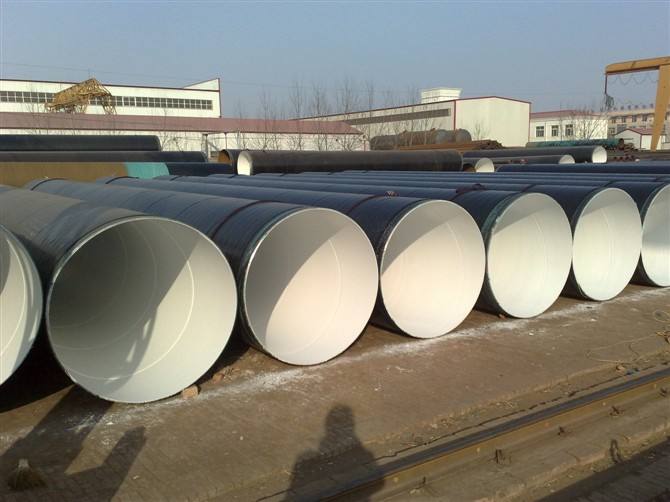

20mm-610mm ASTM Galvanized Seamless Spiral Custom Pipeline

PIC-(20mm-610mm ASTM Galvanized Seamless Spiral Custom Pipeline)

20mm-610mm ASTM Galvanized Seamless Spiral Custom Pipeline

Chemical Composition In % For Spiral Custom Pipeline

| Outer Diameter |

88.9mm---660.4mm |

| Thickness | 3mm--22mm |

| Length | 3m--20m |

| Tolerance | Meet the Standard or acc to your requirement |

| Standard | BS EN 10219, EN 10217, EN10224, ASTM A53, A106, API, JIS G3444, and GB/T3091, GB/T9711 |

| Grade | S235-S355, L235-L355, P195-P460, GR. A, GR. B, X42 ~ X70, J55, STK400, STK500,SS400, Q195, Q215, Q235, and Q345, |

| End Treatment | Beveled or Squared Cut, with or without Caps |

| Surface Treatment |

Varnished, 3PE, 3PP, FBE, Galvanized etc coated. |

| Application | Oil, gas, water transportation, piling, chemical&construction use. |

| Delivery Time |

15---35Days |

| Supply Ability | 30000 metric tons per month. |

Chemical Composition In % For Spiral Custom Pipeline

| Technical requirements | For oil and gas transport | For low pressure fluid conveying |

| Material | Gr.b | Gr.b |

| Pipe body diameter | D<508mm, ±0.75%; D≥508mm, ±0.75% | D≤168.3, ±1.0%; 168.3<D≤508,±0.75%; |

| Wall thickness | D<508mm,+15.0%,-12.5%; D≥508mm, +17.5%,-10% | ±12.5% |

| Bending | ≤0.2% | ≤0.2% |

| Ovality | D≥508mm,≤±1% | ≤±0.75% |

| Bevel | ≤1.59mm | ≤5mm |

| Hydrostatic testing | 100% | 100% |

| Nondestructive testing | 100% non-destructive weld inspection | Ultrasonic flaw detection is 100% |

sale@stpipefitting.cn

sale@stpipefitting.cn

0086-317-5298199

0086-317-5298199  0086-317-5295979

0086-317-5295979 Cangzhou City ,Hebei Province,China

Cangzhou City ,Hebei Province,China