API 5L X56 Seamless Steel Custom Pipeline

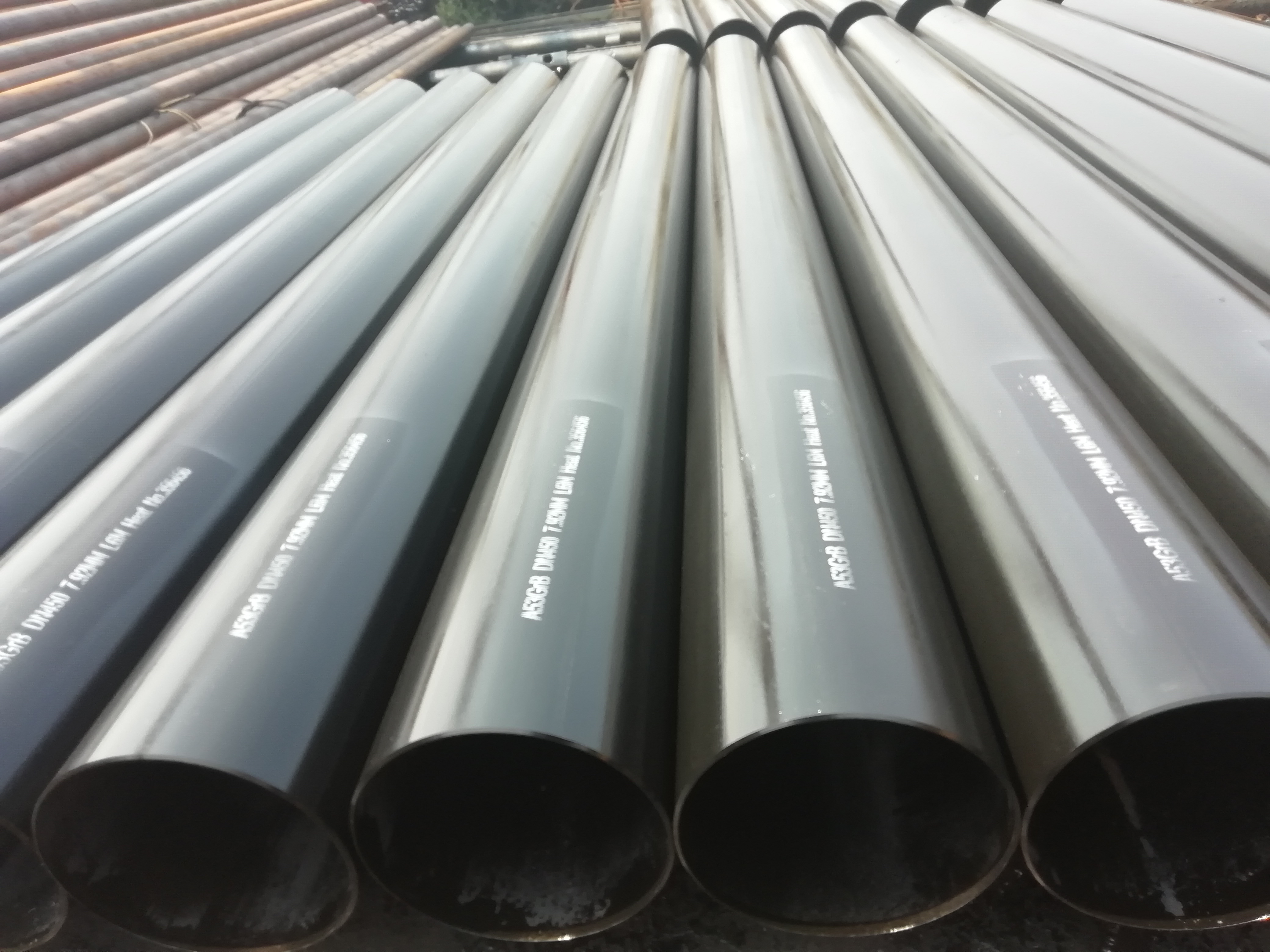

PIC-(API 5L X56 Seamless Steel Custom Pipeline)

API 5L X56 Seamless Steel Custom Pipeline

| Standard | API A106 GR.B A53 Gr.B seamless steel pipe / ASTM A106 Gr.B A53 Gr.B steel tube/AP175-79, DIN2I5L , ASTM A106 Gr.B, ASTM A53 Gr.B/ASTM A179/A192/A213/A210 /370 WP91, WP11,WP22/DIN17440, DIN2448,JISG3452-54. |

| Material | API5L,Gr.A&B, X42, X46, X52, X56, X60, X65, X70, X80,ASTM A53Gr.A&B,ASTM A106 Gr.A&B, ASTM A135,ASTM A252, ASTM A500, DIN1626 |

| Certificates | API5L ISO 9001:2008 TUV SGS BV etc |

| Outside Diameter | 1/2'--24' 21.3mm-609.6mm |

| Thickness | SCH5S, SCH10S, SCH20S,SCH20, SCH30,STD, SCH40,SCH60, SCH80, SCH100, SCH140, SCH160,XS,1.65mm-59.54mm |

| Length | 5.8m 6m Fixed, 12m Fixed, 2-12m Random. |

| Technic | 1/2'--6': hot piercing processing technic 6'--24' : hot extrusion processing technic |

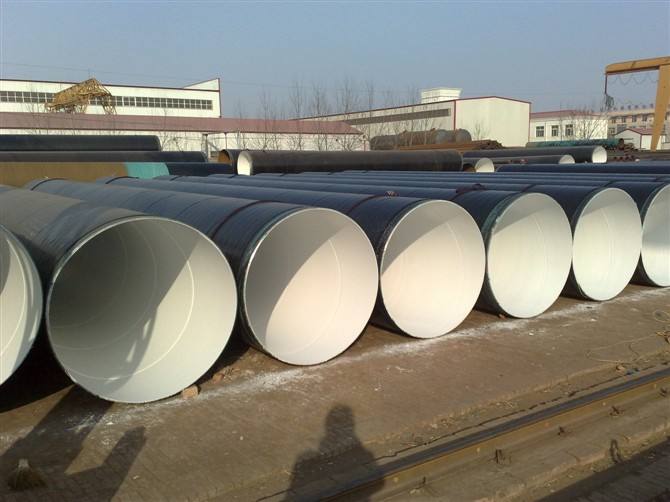

| Surface Treatment | Black Painted, Galvanized, Natural, Anticorrosive 3PE coated,polyurethane foam Insulation . |

| Packing | Bundles or In bulk. bundled pipes with two slings at the both end for easy loading and discharging, |

| Application | Oil pipe line, Drill pipe, Hydraulic pipe, Gas pipe, Fluid pipe,Boiler pipe,Conduit pipe, Scaffolding pipe pharmaceutical and ship building etc. |

API 5L Seamless Steel Pipe Chemical components & mechanical properties

| Standard | Grade | Chemical Components (%) | Mechanical Properties | |||||

|

ASTM A53 |

C | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) | |

| A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.06 | ≥330 | ≥205 | |

| B | ≤0.30 | - | ≤1.2 | ≤0.05 | ≤0.06 | ≥415 | ≥240 | |

| ASTM A106 | A | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥415 | ≥240 |

| B | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥485 | ≥275 | |

| ASTM SA179 | A179 | 0.06-0.18 | - | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 |

| ASTM SA192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 |

|

API 5L PSL1 |

A | 0.22 | - | 0.9 | 0.03 | 0.03 | ≥331 | ≥207 |

| B | 0.28 | - | 1.2 | 0.03 | 0.03 | ≥414 | ≥241 | |

| X42 | 0.28 | - | 1.3 | 0.03 | 0.03 | ≥414 | ≥290 | |

| X46 | 0.28 | - | 1.4 | 0.03 | 0.03 | ≥434 | ≥317 | |

| X52 | 0.28 | - | 1.4 | 0.03 | 0.03 | ≥455 | ≥359 | |

| X56 | 0.28 | - | 1.4 | 0.03 | 0.03 | ≥490 | ≥386 | |

| X60 | 0.28 | - | 1.4 | 0.03 | 0.03 | ≥517 | ≥448 | |

| X65 | 0.28 | - | 1.4 | 0.03 | 0.03 | ≥531 | ≥448 | |

| X70 | 0.28 | - | 1.4 | 0.03 | 0.03 | ≥565 | ≥483 | |

| API 5L PSL2 | B | 0.24 | - | 1.2 | 0.025 | 0.015 | ≥414 | ≥241 |

| X42 | 0.24 | - | 1.3 | 0.025 | 0.015 | ≥414 | ≥290 | |

| X46 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥434 | ≥317 | |

| X52 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥455 | ≥359 | |

| X56 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥490 | ≥386 | |

| X60 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥517 | ≥414 | |

| X65 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥531 | ≥448 | |

| X70 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥565 | ≥483 | |

| X80 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥621 | ≥552 | |

sale@stpipefitting.cn

sale@stpipefitting.cn

0086-317-5298199

0086-317-5298199  0086-317-5295979

0086-317-5295979 Cangzhou City ,Hebei Province,China

Cangzhou City ,Hebei Province,China